You either pay now…or pay more later.

When money is tight, some may think that cutting preventive maintenance is the best option. Before taking that approach, let’s have a good understanding of the role and function of maintenance . Studies show that the return on investment from a maintenance approach that is proactive rather than reactive is proven to increase savings and overall reliability time and time again. Whether you are a commercial, industrial or on-premise laundry (OPL), a regular scheduled maintenance program can keep equipment running efficiently and reduce overall repair costs.

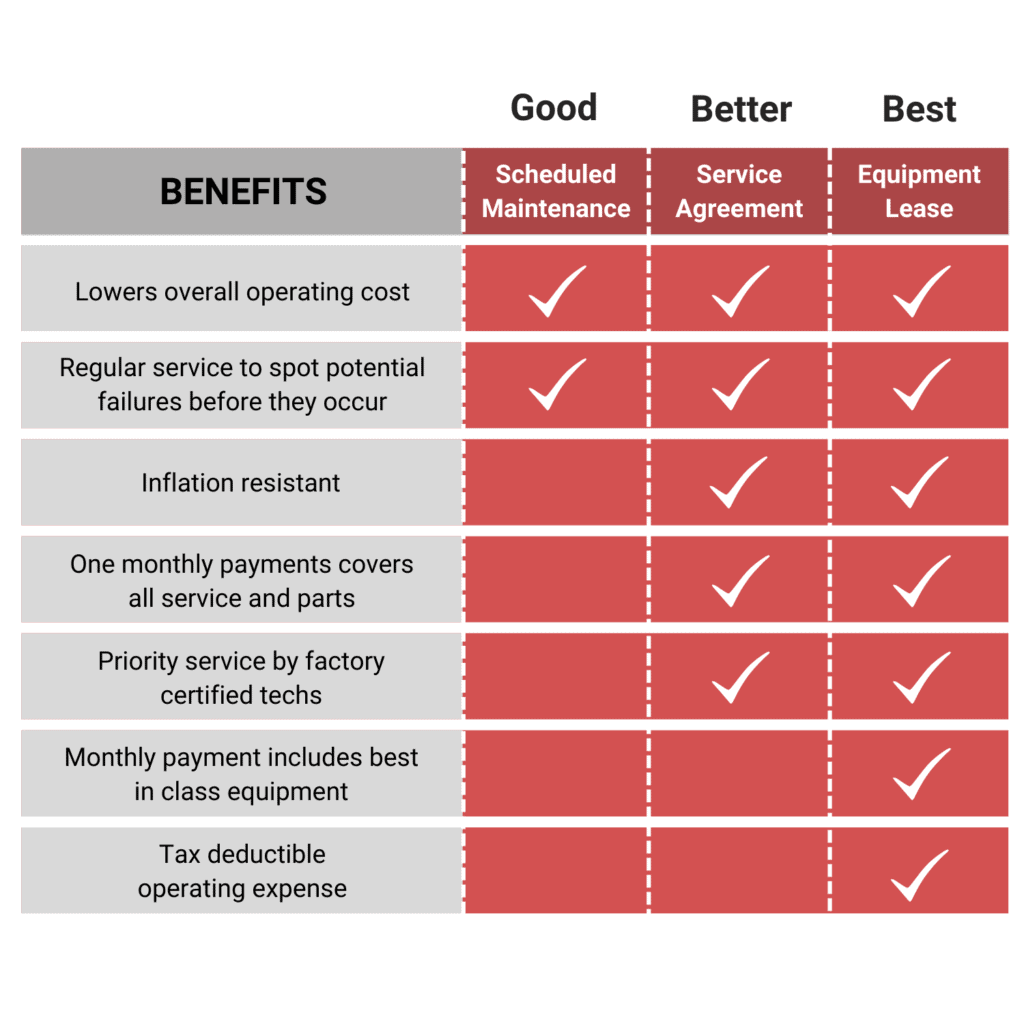

At the bare minimum, you should at least be on a scheduled maintenance program. This is a program that checks your equipment’s performance each quarter to ensure effectiveness and help identify problems before they arise. This is the bare minimum we suggest for our customers. We have other programs that may suit your needs even better. You can check that out here.

There are still steps you can take in between your quarterly maintenance to help extend the life of your equipment and ensure safety.

11 tips to maintain your commercial laundry equipment between scheduled maintenance inspections.

1. Keep the exterior of laundry equipment clean.

No matter what type of commercial laundry equipment you use, keeping the outside of it clean is always an easy first step. Regular cleanings can help prevent lint and other debris from getting inside the machines and causing damage. Regular cleaning can also prevent leftover soaps and detergents from corroding and damaging the machines.

2. Clean the soap dispensers.

Soaps, powdered detergent, and boosters can quickly gum up dispensers. Regularly cleaning out these dispensers or soaking them in water can help prevent major clogs or corrosive damage that might require you to completely replace them.

3. Clean or replace the water filter inlet screens regularly.

These screens can become blocked by small particles over time, which may prevent proper water flow into the machine.

4. Check inlet and outlet hoses regularly.

These hoses can get sediment buildup and tiny leaks. Inspecting and changing these as needed can help prevent loss of water and high water bills.

5. Check the belts from the motor to the drum on machines.

Look for things like fraying or splitting and replace these belts as needed. Generally, these have to be replaced about twice each year and should be caught by your service provider, but it doesn’t hurt to check.

6. Check seals around washer doors.

Regularly checking for and removing buildup around the seals on your washers can help make sure your equipment always has a water-tight seal to prevent leaking.

7. Leave washer doors open when possible.

Leaving the washer doors open when they are not in use, can help ensure air circulates to the interior and the machines dry properly.

8. Check lint filters after each load.

It is not uncommon for employees or customers to forget to clean out the lint filter on dryers between loads. You should consistently be monitoring this to help prevent potential fires and overheating.

9. Set a Daily Maintenance Routine.

A regular schedule will keep your equipment in good shape. Set a schedule for yourself and your crew to follow and keep track of tasks that need to be done regularly. We have a list you can download to use and check off as they are completed to ensure no duty gets forgotten

10. Have a Reliable Commercial Laundry Repair Service on Speed Dial.

When your equipment is acting up or needs specialized care, it is relieving to have a commercial laundry servicing company on your side that you can trust. You will not have to worry about machines being out of commission for too long with trained and experienced technicians. Choose a reliable and trustworthy local company to have on speed dial when an issue arises. Our service agreement at Southeastern makes this process even easier because it is one set monthly payment that covers all service calls and parts needed to repair. Our customers say our service agreement removes any hesitation and the “I can try to fix it myself” mentality because there are no additional costs associated with repairs.

11. Sign Up for a Dependable Service and Maintenance Program

One of Southeastern Laundry’s most important maintenance tips for commercial laundry equipment is upkeep. That is why we have a few different service and maintenance programs. We want to help take some of the responsibility off your plate while still focusing on your bottom line.

The time spent on planned vs. unplanned maintenance is a key indicator of pay now or pay more later. You can continue to run your machines to failure and keep expecting a different result or you can view your maintenance program as an investment that is an on-premise risk management and insurance provider that will keep your vision alive and well.

While you may be able to perform many routine maintenance duties on your own, more specific training and knowledge is required to properly maintain your machinery. At the bare minimum, we suggest a scheduled maintenance program, but more often than not, a service agreement fits the needs of our customers even better. If you would like to learn more about our service options, fill out the form below and we can talk through what options best fir your needs.